1. Program Introduction

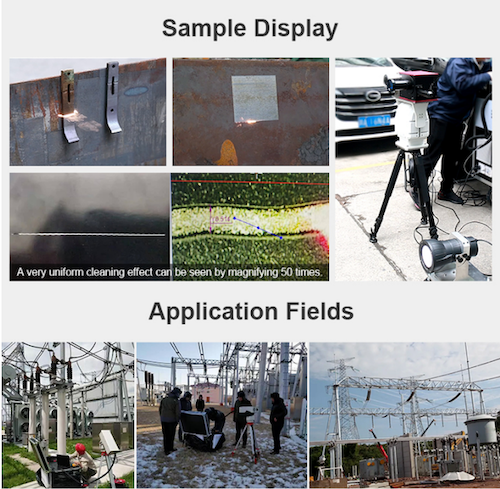

The equipment is used for remote laser cleaning and rust removal operations on power grids, substations, and other locations. It can completely remove the paint and rust from the target surface at a safe distance of 6-10m, with no surface residue, no obvious oxidation color, no blackening, no obvious boundary at the lap, no injury to the substrate, no change in the surface hardness and roughness of the container substrate before and after cleaning. The state of the metal body surface after cleaning will not impact the paint’s repainting.

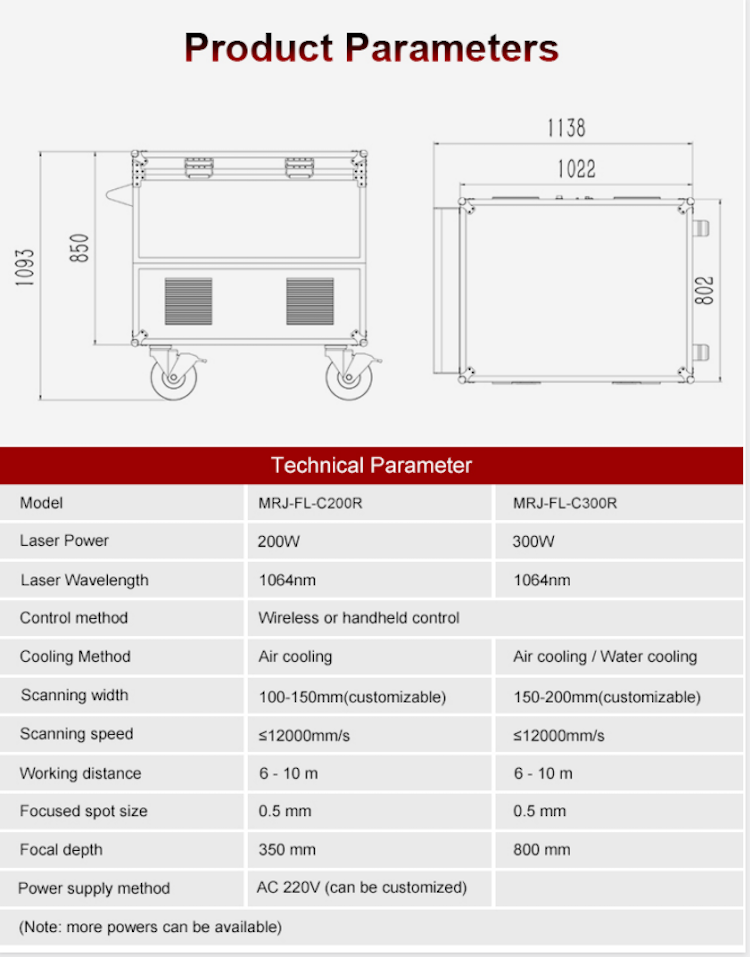

2. Equipment Introduction

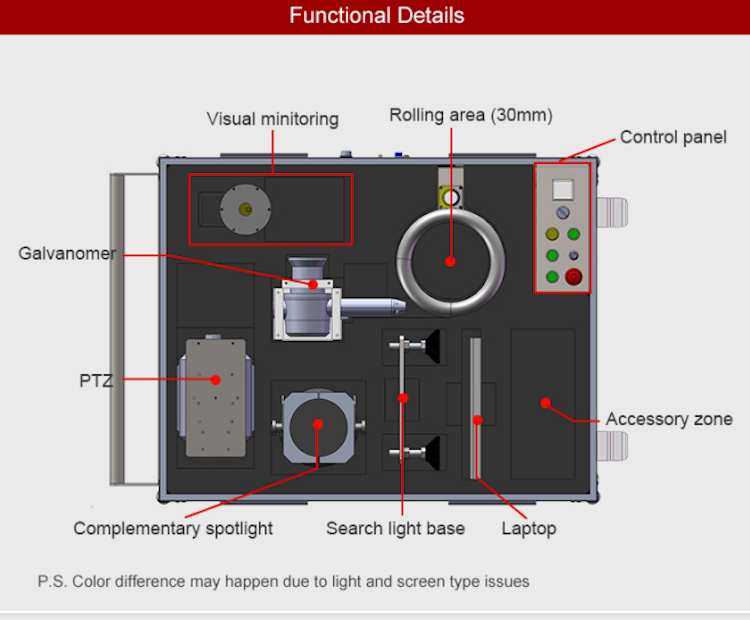

The equipment is a remote-controlled laser cleaning machine used in high-risk environments for long-distance laser cleaning of objects. The cleaning distance is 6-10 m, the cleaning range is 360 degrees for horizontal rotation and ±90 degrees for tilt angle. The device can be controlled by a laptop. The equipment is fixed to the outdoor ground with a tripod, and the cleaning lens is controlled by a high-precision head to clean the light, and the positioning accuracy of the head is ±0.1 degree. A visual monitoring unit is installed next to the lens to transfer the cleaning images to the laptop in real time so the operator can easily observe them. The visual monitoring camera is installed in a special housing that can protect against rain, dew, and dust. The equipment is equipped with a powerful outdoor spotlight that fills the cleaning area with light and makes it easier for the camera to observe. The spotlight is mounted on an adjustable bracket with a 90-degree tilt angle adjustment.

The inside of the equipment is divided into two parts. electrical components. This area is isolated from the whole machine by a partition wall and the internal gas circulation is completed by a special cooling fan and an air inlet with louver. air inlet, both the air inlet and the outlet have a built-in filter cotton to isolate and filter the dust outside. isolate and filter the dust outside. The upper part is filled with foam, which has different placement holes for different parts. The unit has large wheels on the bottom and push-and-pull handles on the side of the cabinet. handles on the side of the cabinet, which can be adjusted to meet the needs of different outdoor movements. The overall chassis is made of an aviation box, which prevents rain from entering it during a light rain. The case is a flip-top design with internal gas struts on both sides, which can be used for stable support after the top cover is lifted to prevent the cover from slipping and damaging cables during machine operation.