Contact us ?

Chengdu MRJ-Laser Technology Co.,Ltd.

Bldg 10, No.28, Xinchuang Rd, West Zone, High-tech Zone, Chengdu, China.

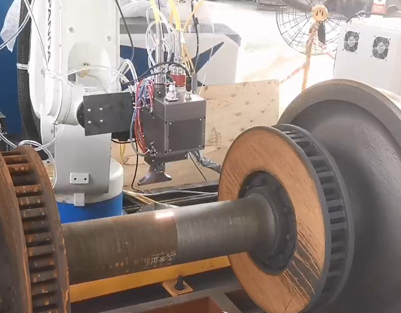

Factory mold cleaning

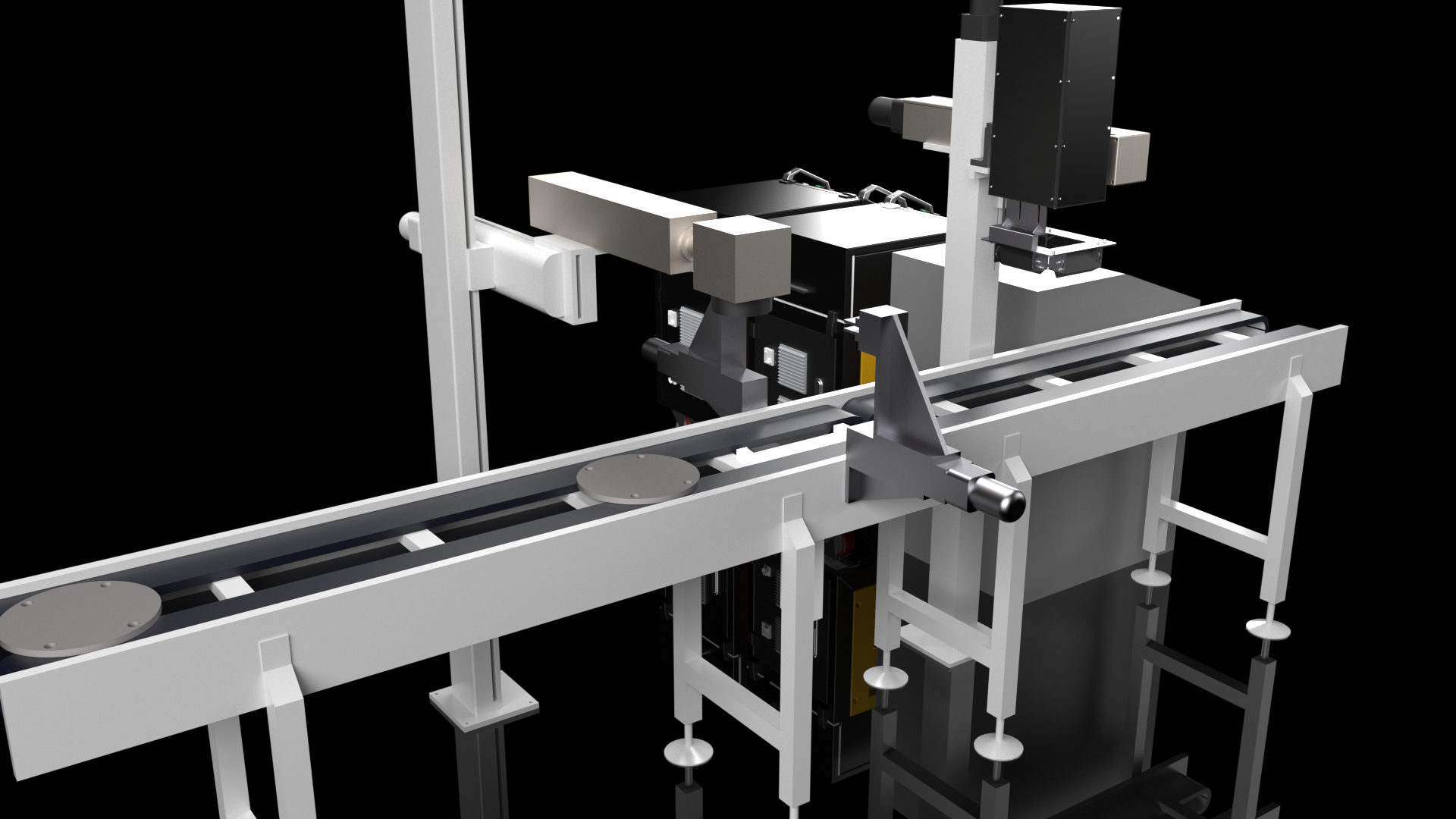

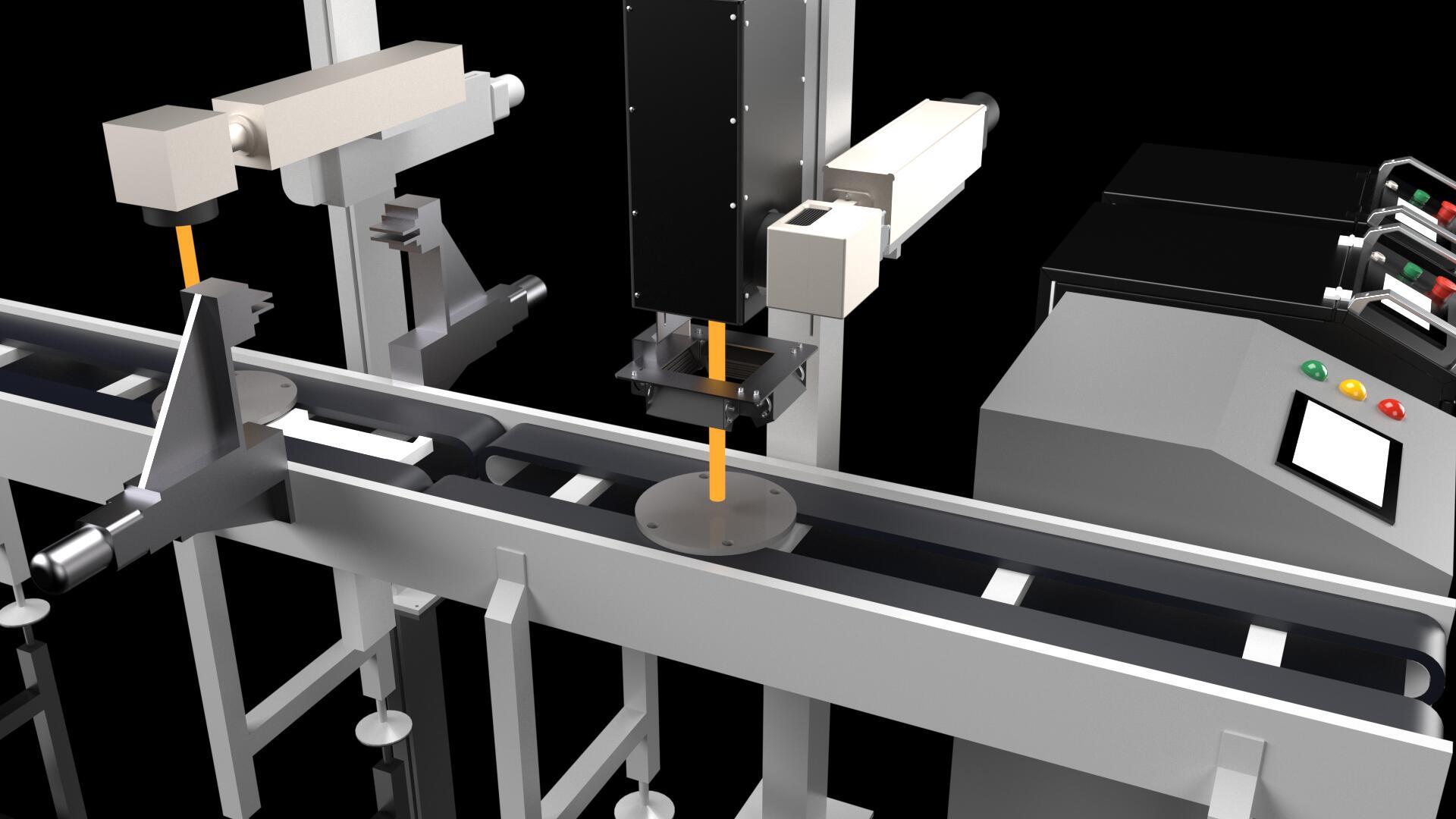

The system consists of two laser cleaning machines, a central control system, conveyors, etc.

A laser cleaning machine is used to clean the surface of the mold. After being turned over by the turning mechanism, both sides can be cleaned. After the cleaning of both sides is completed, the product reaches the bottom of another vision cleaning machine through the conveyor belt. The vision system starts to capture the shape of the ear hole and precisely locates the cleaning position. The vision system generates graphics and transmits them to the cleaning system.

Features

● Complete the cleaning of six molds within 30 minutes.

● Loading and unloading can be done manually or by a mechanical arm.

- No contact

- Highly efficient

- Environment friendly

This system brings higher quality and efficiency to the company, and is a commendable high-tech achievement.

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time

What we can Do

According to your production and processing needs, we will provide you with relevant product knowledge and professional technical consulting services at any time, as well as free incoming material testing. Welcome to visit our factory.

Laser cleaning compared to traditional cleaning

It is more convenient, faster, and more efficient than traditional cleaning. With almost no harm to the mold itself and no pollution to the environment, it is the first choice for rubber molds

How do you provide service in Europe, what is the equipment maintenance like?

24-hour online service, with video instruction & guidance, and technical training, which are lifelong available for free. Our company can also provide door-to-door service if required. If there’s a quality failure with the laser source within three months of receiving the goods, it will be replaced free of charge, We have agents in 14 countries around the world, and they can offer you help if needed. Denmark, Croatia.