Contact us ?

Chengdu MRJ-Laser Technology Co.,Ltd.

Bldg 10, No.28, Xinchuang Rd, West Zone, High-tech Zone, Chengdu, China.

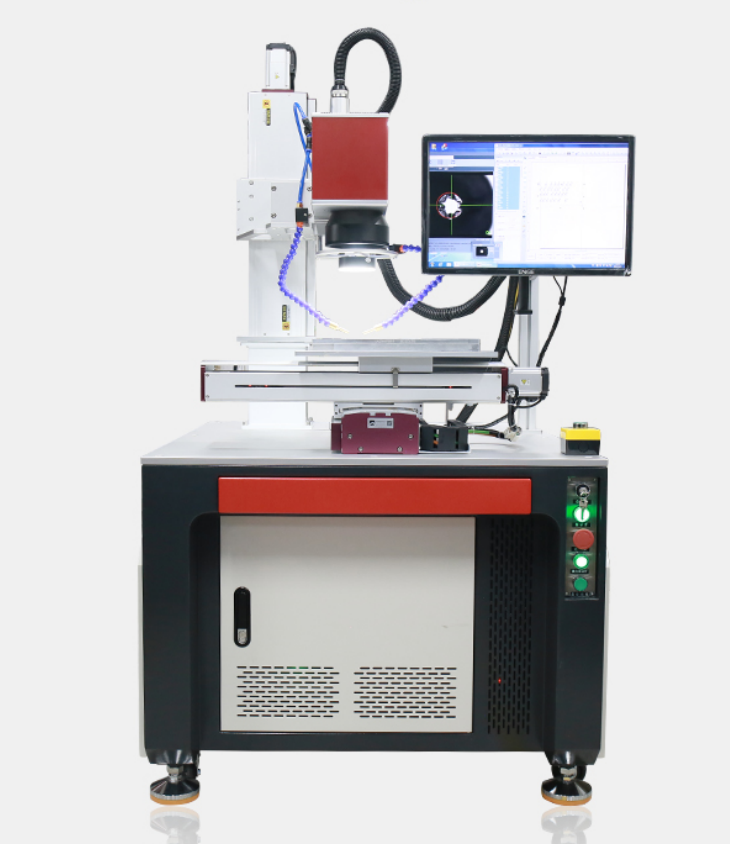

Galvanometer laser welding

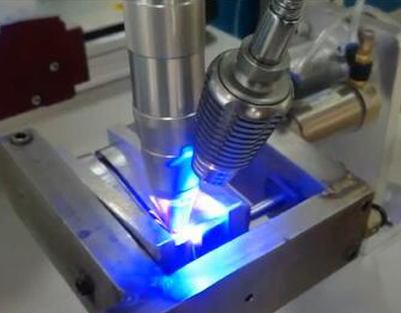

This is an efficient, safe, and stable high-power fiber laser galvanometer welding machine for power battery tabs, poles, and other materials. It has high power, ideal beam quality, is maintenance-free, has high electro-optical conversion efficiency, etc. Equipped with a precision laser scanning galvanometer and unique design, it is the most suitable high-power continuous laser welding equipment in the battery pack industry at present. It can weld various metal connection pieces such as aluminum, copper, and nickel.

The laser beam quality of this equipment is excellent, the welding speed is fast, and the welding pool is beautiful and firm, which brings efficient, stable, and perfect welding solutions for the lithium battery welding process.

Equipment Advantage

1. The welding head adopts the galvanometer scanning type, which is compatible with the welding modes of various power battery packs

2. Controlled by industrial PC, it can carry out graphic welding processing composed of laser points, straight lines, circles, squares and other planes arbitrarily

3. The welding head adopts water cooling cycle for local cooling to ensure the stability and consistency of welding quality

4. The welding field mirror adopts imported lenses, which can withstand the high temperature of laser power

5. The air knife blowing function is used during welding to prevent the smoke welding slag from affecting the welding effect

6. When welding, the pneumatic top pressure device is used to compress the connecting piece and the tab to prevent the phenomenon of false welding caused by poor fit

- Can work in a harmful environment

- Stable quality

- Shorten the preparation period for product modification

Compared with the traditional automatic welding machine that moves the workpiece through the stepping servo motor for welding, the galvanometer laser welding greatly reduces the idle positioning time during single-point welding, and the welding speed is greatly improved. Compared with The efficiency of the traditional electric workbench is increased by 3-5 times, and the overall production efficiency is about 8 times that of ordinary laser welding.

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time

What we can Do

According to your production and processing needs, we will provide you with relevant product knowledge and professional technical consulting services at any time, as well as free incoming material testing. Welcome to visit our factory.

Laser welding is one of the most important technologies in industrial material processing applications

It can be used in various industrial manufacturing such as mechanical parts, auto parts, lithium battery sealing, silicon steel plate, electronic components, precision spot welding, and sealing welding. It is widely used in aerospace, machinery, electronics, communication, power, chemical industry, Automobile manufacturing, and other industries

Exported to more than 60 countries and regions around the world

At present, our products have been sold to more than 70 countries around the world, and we have agents in 14 countries around the world. For the specific distribution, please consult the relevant sales managers.

General agents: USA, Canada, Germany, France, Spain, Norway, Hungary, Serbia, Iran;

Exclusive agents: Japan, Indonesia, Saudi Arabia, Denmark, Croatia.

Remote installation guidance

With video instruction & guidance and technical training, which are lifelong and available for free. Any repair or replacement under warranty terms will be free of charge, and the freight shall be borne by the customer. Our company can also provide door-to-door service if required.