Contact us ?

Chengdu MRJ-Laser Technology Co.,Ltd.

Bldg 10, No.28, Xinchuang Rd, West Zone, High-tech Zone, Chengdu, China.

Remote Laser Cleaning System

The equipment is used for remote laser cleaning and rust removal operations on power grids, substations, and other locations. It can completely remove the paint and rust from the target surface at a safe distance of 6-10m, with no surface residue, no obvious oxidation color, no blackening, no obvious boundary at the lap, no injury to the substrate, no change in the surface hardness and roughness of the container substrate before and after cleaning, and the state of the metal body surface after cleaning will not have an impact on the repainting of the paint.

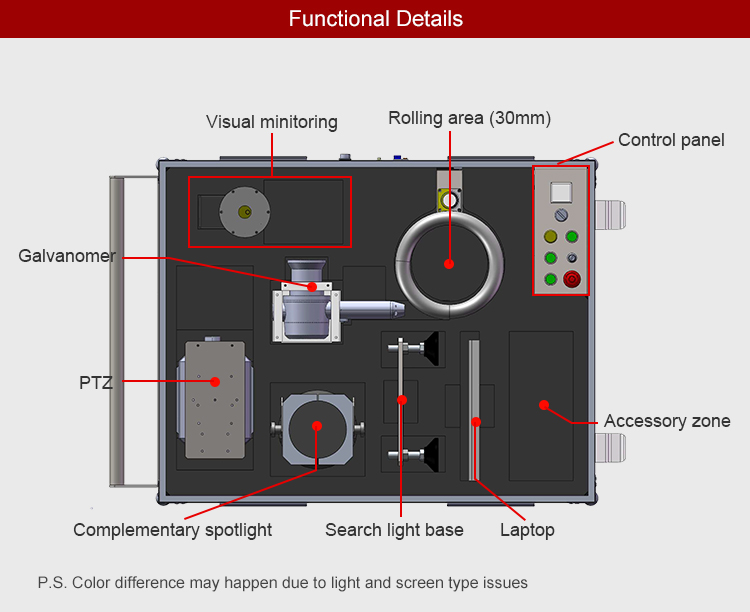

General diagram of the equipment

The equipment is a remote laser cleaning machine, used in high-risk environments for long-distance objects for laser cleaning. The cleaning distance is 6-10m, the cleaning range is 360° for horizontal rotation and ±90° for pitching angle. The equipment can be controlled by a laptop. The equipment is fixed on the outdoor ground by a tripod, and the cleaning lens is controlled by a high-precision head to clean the light, and the positioning accuracy of the head is ±0.1°. A visual monitoring device is installed next to the lens to transmit the cleaning images to the laptop in real-time for easy observation by the operator. The visual monitoring camera is installed inside a special housing, which can achieve the effect of rain, dew, and dust protection. The equipment is equipped with a high-powered outdoor spotlight to fill the cleaning area with light and facilitate observation by the vision camera. The spotlight is mounted on an adjustable bracket with a 90° tilt angle range adjustment.

- Remote Cleaning

- Accurate Positioning

- Safety Assurance

The system is suitable for remote laser derusting operation of power grid, substation, etc, The paint, rust and stains on the targetmaterial surace can be completely removed at a cleaning distance of 6-10m, no surface residue, no blackening, no damace to thesubstrate, and the surface hardness and roughness do not change before and after cleaning, the cleaning will also not affect the respraying of paint.

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time

What we can Do

According to your production and processing needs, we will provide you with relevant product knowledge and professional technical consulting services at any time, as well as free incoming material testing. Welcome to visit our factory.

Pre-welding cleaning of auto body, roof cover, side wall, bottom plate, etc

Laser cleaning before welding can significantly reduce the black ash and porosity defects of welded joints, strengthen the welding uniformity and improve the welding quality.

Pre-welding cleaning of transmission gear

Adopting laser cleaning technology instead of the original ultrasonic cleaning. reduced the operating cost by more than 50%, and increased the product’s qualified rate from 90% to over 99%.

Laser cleaning before and after welding of aluminum body parts

Using laser cleaning instead of manual grinding, reduced the labor intensity. increased the processing efficiency and quality, improved the workshop operating environment.