Contact us ?

Chengdu MRJ-Laser Technology Co.,Ltd.

Bldg 10, No.28, Xinchuang Rd, West Zone, High-tech Zone, Chengdu, China.

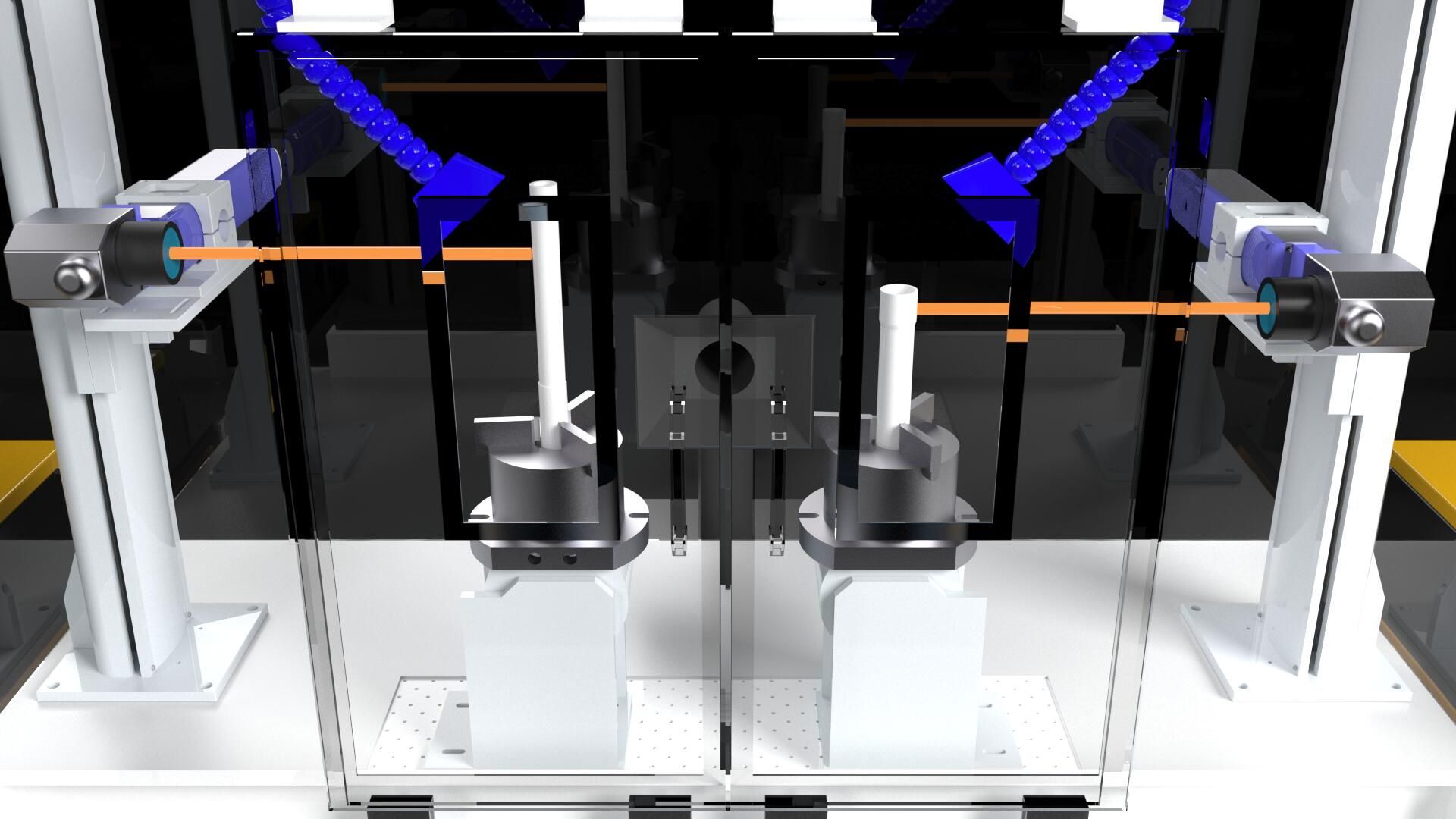

Automatic Rubber Mold Cleaning System

The cleaning system consists of two cleaning machines, a cleaning head installation column, an electric rotating shaft + automatic clamping three-jaw chuck, a dust removal system, a laser protective cover, etc.

Automated Laser Cleaning Solution

● According to customer requirements, the system adopts manual loading and unloading.

● Double-station, the vertical cleaning method, cleaning the male shaft and female shaft at the same time, which can improve the cleaning efficiency.

● Each cleaning is less than 25 seconds, which greatly saves time compared with traditional cleaning methods.

- Double-station

- No Contact

- Save Time

Application industry:

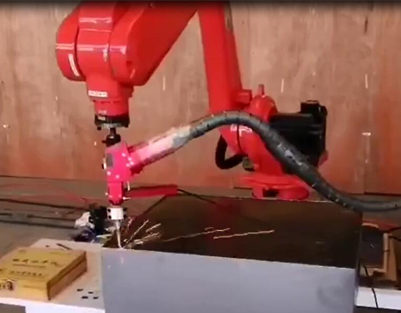

metal surface rust removal, paint removal, surface oil, stain and dirt cleaning, welding surface, spray surface pretreatment, surface coating, plating and oxide layer removal, rubber mold residue cleaning, stone carving cultural relics and other surface dust Cleaning of dangerous industries such as urban graffiti, printing cylinders, lubricating oil on precision machinery industrial parts, building exterior walls, nuclear pipelines, etc., removal of particles and pin removal of semiconductor components, microelectronic devices, memory templates, silicon templates, etc. Oxide

Our Best Solutions

Advanced Technology

Expert Engineers

Delivery on Time

What we can Do

According to your production and processing needs, we will provide you with relevant product knowledge and professional technical consulting services at any time, as well as free incoming material testing. Welcome to visit our factory.

Laser cleaning has great application potential

Laser cleaning has great application potential in various large-scale industries such as mold production, the aviation industry, the electronics industry, weaponry and equipment, shipbuilding, and maintenance. In these industries, the above-mentioned low-to-medium power and hand-held cleaning systems are not enough. Therefore, future laser cleaning technology will inevitably develop in the direction of high power (1000W and above), automation, and intelligence.

Have obtained more than 30 invention patents

Has won more than 30 invention patents, has complete independent intellectual property rights, quality control strictly implements the ISO9001 quality management system, and the products have passed the EU CE and US FDA certification

Excellent after-sales service

7*24 hours online service guarantees customers can solve any problems they may encounter.