Cleaning is a crucial part of industrial production. Traditional cleaning methods, such as mechanical cleaning and chemical cleaning, can meet the production needs to a certain extent, but there are often problems such as inflexibility and pollution of the environment. With the progress of science and technology, laser cleaning technology came into being, with its high efficiency, environmental protection, and non-contact characteristics, and gradually became the new favorite in the field of cleaning. Among them, single mode and multi-mode in fiber pulsed laser are the two most commonly used laser types. So, what exactly is the difference between them? What are the advantages and disadvantages of each? For which application scenarios?

What is Singlemode and Multimode

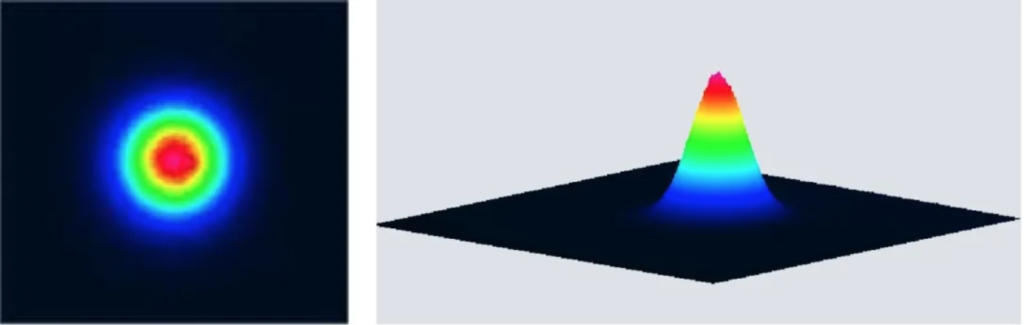

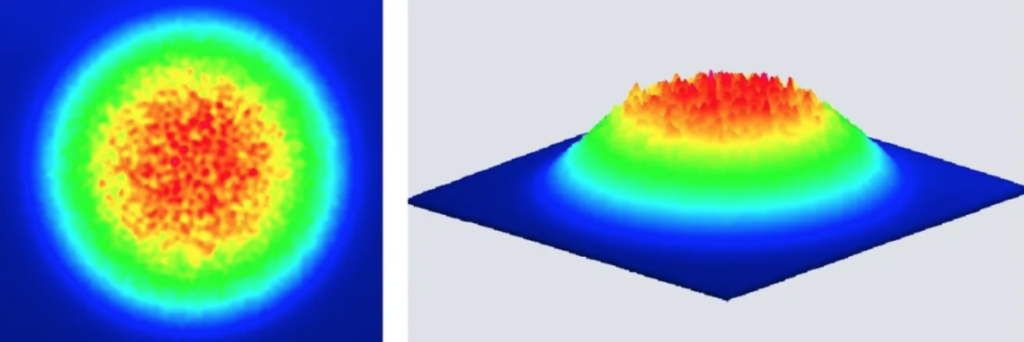

The mode of a laser usually refers to the state of energy distribution in the plane of the laser perpendicular to the direction of propagation and is divided into single mode and multi-mode. Single mode refers to the laser in the work, only one mode of laser output. Single mode energy intensity from the center to the outer edge of the gradual weakening of the energy distribution in the form of a Gaussian curve, the beam is called the base mode Gaussian beam. Single mode output laser beam has high beam quality, small beam diameter, small divergence angle, energy distribution close to the ideal Gaussian curve, and other characteristics. In addition, the single mode has better-focusing characteristics, small focused spots, and strong mode stability, which is suitable for cleaning scenes that require strong removal, such as rust.

Multi-mode laser output spot is often combined by a variety of modes, the spot energy distribution is more uniform, and the more modes, the more uniform the energy distribution, the beam is also known as the flat-top beam. Compared with single mode, multi-mode laser beam quality is poorer, the divergence angle is larger, requiring a larger aperture optical system transmission and the focusing spot is larger than single mode. However, multimode makes it easier to achieve large single-pulse energy, high peak power, and high average power output with uniform energy distribution, which is advantageous for cleaning scenarios that require low damage and high efficiency, such as molds and dies.

What are the advantages and disadvantages of single-mode vs. multi-mode laser cleaning?

Single-mode lasers are suitable for removing strongly adherent contaminants such as green rust due to their good beam quality, small focused spot,s and high energy density, as well as for cleaning thin materials and precision parts that are sensitive to heat input. However, due to the single-mode energy being too concentrated, in the cleaning may cause some damage to the substrate material.

For the mold and other requirements of the cleaning of the substrate material after the scene without damage, it is necessary to choose a multi-mode laser. The multi-mode beam energy distribution is uniform, high peak power, and the peak power density is higher than the damage threshold of the pollutants and lower than the substrate, so the cleaning can effectively remove the pollutants without destroying the structure of the material surface. In addition, the focused spot of the multimode is larger, and for scenarios in which single-mode and multimode can achieve the same cleaning effect, the cleaning efficiency of the multimode is usually higher. However, for strongly adhering contaminants, multimode laser cleaning may not be sufficient.

Application scenarios of single-mode and multi-mode lasers

Single mode main application scenarios:

Metal Descaling: The high energy density of single-mode lasers makes them ideal for metal descaling, which can efficiently remove the rust layer on metal surfaces, the higher the laser power, the stronger and more efficient the rust spot removal ability. 1000W high power single mode pulsed laser, QBH output for easy integration, with strong cleaning ability, high efficiency, and other advantages.

Weld Oxide Cleaning: In the welding process, due to the high temperature of the process, the weld seam and around the formation of oxides and material precipitation debris is easy to affect the quality and appearance of the weld, 200 ~ 500W single-mode laser, can accurately remove oxides, to ensure that the appearance of the weld and the quality of the weld.

Precision parts cleaning: 100~200W single-mode laser, QCS output, strong cleaning ability, small heat output, small deformation of the material after cleaning, small thermal impact.

Multi-mold main application scenarios:

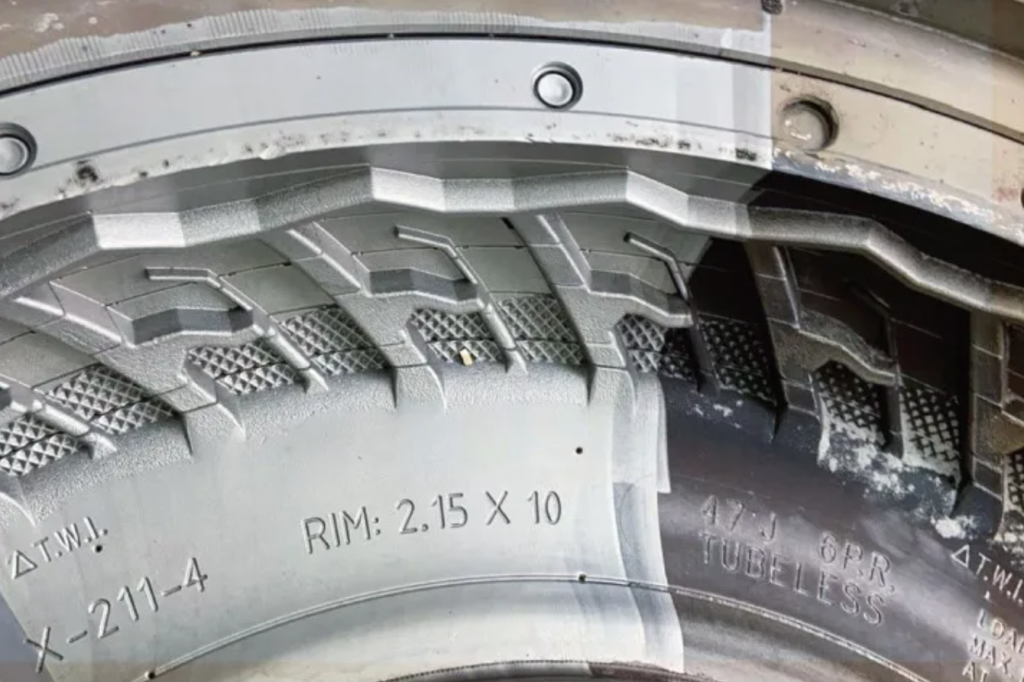

Mold Cleaning: Molds may accumulate residues during use, such as plastic, metal fragments, dust, etc. These residues will affect the surface quality of the product and cause product defects. Regular cleaning of molds can prevent corrosion and wear, thus extending the service life of the molds. Due to the large difference in the characteristics of the mold substrate and the contaminants, the use of tophat beam can effectively remove the contaminants and do not hurt the mold. 500~1000W square spot multimode laser, high efficiency in cleaning the mold, no damage to the substrate.

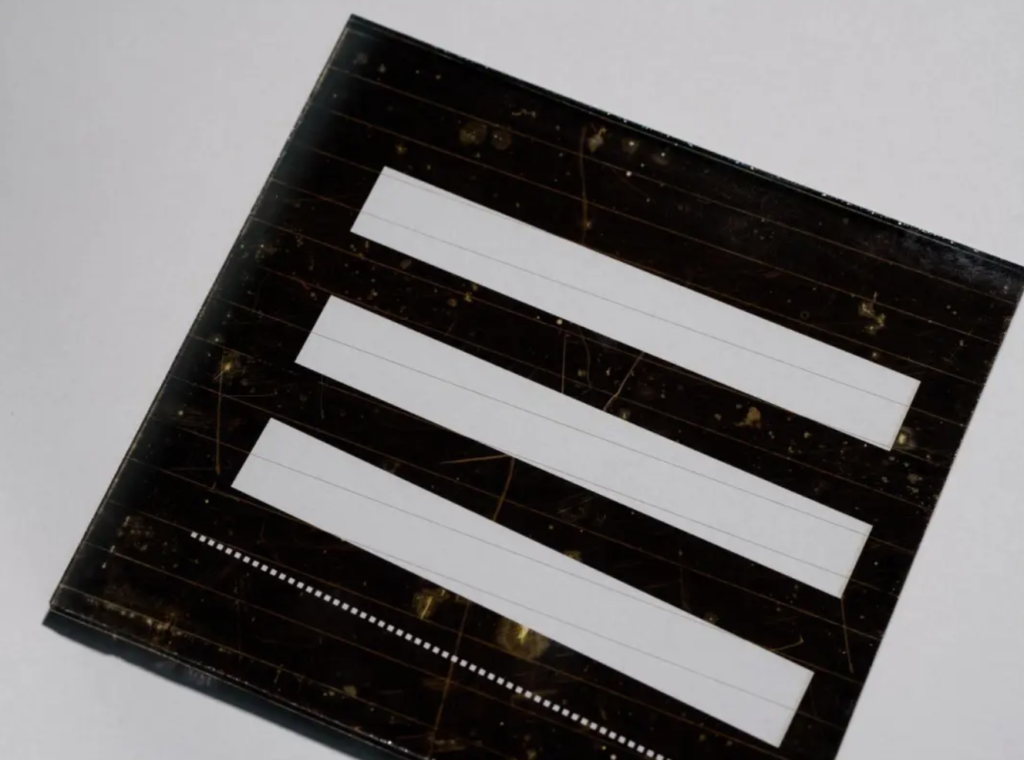

Calcium Titanium Ore Cell Edge Cleaning: refers to cleaning the film layer at the edge of the thin film solar cell, creating an insulated area for subsequent encapsulation.1000W pulsed laser, square spot output, uniform energy distribution, high peak power, able to clean the film layer in one go, no damage to the glass, high efficiency.

Laser texturing: Using the laser to burr the material surface can significantly improve the adhesion of the material surface. According to the different requirements of the roughness of the burring, can use 5mJ, 15mJ, and 50mJ different single pulse energy of the multi-mode laser, to ensure the efficiency of the burring at the same time to achieve the different requirements of the roughness?